2024 was another busy year for the biochar program at Sonoma Ecology Center. Here are a few highlights:

We successfully navigated an EPA process to change the way clean cellulosic biomass is viewed by the EPA and the BAAQMD for use in pyrolysis systems.

Instead of categorizing clean cellulosic biomass as MSW when used in pyrolysis systems or some gasification systems it is now considered a “traditional product” or process ingredient. This national ruling should now make it easier for entrepreneurs around the country get their systems permitted without costly and onerous monitoring and adherence to other regulations that would make such projects unaffordable. Of course, it is critical for all such systems to have modern pollution control devices such as thermal oxidizers and to adhere to other requirements of their local air districts. This EPA ruling, however, which took over 9 months and significant efforts from other groups as well such as the US Biochar Association and USBI, is a major win for the biochar community. Here is the key paragraph from this ruling:

“What is the status of clean cellulosic biomass that is processed to make biochar?

Clean cellulosic biomass that is processed to make a biochar product using pyrolysis or a similar process would not be considered discarded and would not be a secondary material or solid waste for the purposes of the Clean Air Act. Biochar produced from clean cellulosic biomass is considered a “traditional product” for the purposes e of the regulations found at 40 CFR Section 241.3(d)(2)(iv)”

You can read the flyer that EPA issued regarding this ruling here:

Continued to pressure the BAAQMD to complete our application for an Authority to Construct permit for our ARTi Pyrolysis System startup at Napa Recycling.

After successfully obtaining a critical determination categorizing the use of wood chips as a process ingredient rather than MSW during the 9-month EPA permitting process described above, we restarted the BAAQMD permitting process in August 2024 that had stalled pending the outcome of the EPA process. After many hours spent supplying additional technical and operational information to the air district we finally received the Authority to Construct permit on Feb. 20th, 2025. This ended a long, three+ year journey to permit our relatively small-scale, demonstration pyrolysis operation in the Bay Area and we are now on track to commission the unit and to perform full emissions testing required by the BAAQMD by March 30th.

Delivery of the ARTi Pyrolysis unit. /Baltar

10 Green Schoolyard Plans Completed, 24 Trees Planted at 2 Schools

In 2023 we received 2 separate CAL FIRE-funded Green Schoolyards Planning grants to develop landscape and infrastructure improvements at 4 elementary schools in south Santa Rosa and 8 elementary schools in Pittsburg (in the eastern Bay Area). Working with key partners Bay Tree Landscape Design in Santa Rosa and DC Architects/Gates and Associates Landscape Designs in Pittsburg, 10 comprehensive plans were successfully developed that included planting shade trees, adding outdoor classrooms, and removing asphalt and replacing with natural play areas. Also included in these plans was development and expansion of SEC’s environmental education program into these schools for the 2nd through 5th grades.

One of the plans to green the campus at Taylor Mountain Elementary School in Santa Rosa, CA. / Bay Tree Design

During the CEQA planning process at 2 schools in Santa Rosa we encountered an issue that would have limited construction: the historic presence of the Tiger Salamander on school grounds. We were, however, able to negotiate a grant amendment with CAL FIRE that allowed us to hand-plant a total of 24 trees at these two schools with help from parent, student and staff volunteers. Biochar was used in these plantings.

Tree planting at Bellevue Elementary / Baltar

We also submitted 2 grant proposals to CAL FIRE under a federal Inflation Reduction Act (IRA)-funded program to implement these plans at one school in Santa Rosa and one in Pittsburg, and we were one of only 5 grantees in the state to be awarded a grant to plant the trees and construct the greening features at Stoneman Elementary in Pittsburg. Unfortunately, these funds are now frozen as part of the efforts to cut all climate-related projects funded through the IRA and we are currently looking for other funding sources to implement all of the plans we developed.

Worked with Earth Foundries on a Bioswale project at Veggielution Farms in San Jose

We have worked on a number of consulting projects with Earth Foundries over the last few years, including a technology review, a biochar use study in the East Bay Regional Park System for biochar produced during a major fuels reduction project at Chabot Regional Park in Oakland, several manure/compose/biochar field trials, and a biochar-infused bioswale project at Veggielution, an urban farm in San Jose. Earth Foundries is a woman-owned, action-oriented company based in Santa Clara County dedicated to “ending California’s catastrophic wildfires” as well as contributing to the growing body of scientific knowledge in a number of important use-cases. Focused initially on the better management of low-value materials and production of biochar using a large-scale, in-forest processing technology called the Tigercat Carbonizer, Earth Foundries has also been successful in securing grants for a number of other actions, and we have very much enjoyed working with them on these projects.

Spreading biochar in the bioswale / Baltar

Worked as Advisors to the Sonoma County Wood Recovery and Utilization Project

This project was managed by Temra Costa of Regenerative Forest Solutions and funded by the North Coast Resource Partnership through the Governor’s Office of Climate and Land Use Innovation. The goal was to develop a report quantifying the amount of un-merchantable forestry-related biomass that could potentially be sustainably utilized in innovative ways rather than simply burning or chipping it. Research was also done on potential locations for a

Get more information about the project HERE.

biomass campus where recovered biomass could be stored and used by a number of different businesses such as woodworking, manufacture of poles to be used as fenceposts or for other construction purposes, and the production of biochar.

Managed 8 days of Emissions testing at the USFS Fires Science Lab

Testing hood at the USFS Fire Science Lab / Baltar

Conservation burn fully engulfed in the USFS Fire Science Lab / Baltar

Kiln Burn expert Cuauhtemoc Villa starts a kiln test fire at the USFS Fire Science Lab / Baltar

As part of another CAL FIRE-funded project awarded to the San Luis Obispo Air Pollution Control District, we helped manage 10 days of emissions testing in September at the USFS Fire Science Lab in Missoula, Montana. We compared emissions from a Ring of Fire Kiln, the conservation burn (top lit) pile method, and the standard burn pile method. The amount of carbon produced as biochar was also measured between the three burn methods. After conducting many trainings and demonstrations of the Ring of Fire kiln over the last 5 years it was clear that these kilns (manufactured by Wilson Biochar) produced significantly less smoke than standard burn piles, we wanted to quantify these results along with a range of other pollutants including methane, C02, and black carbon.

While final results will be written up in a peer-reviewed journal by Dr. James Amonette, preliminary results will be available in late March, 2025 and will be published here in April.

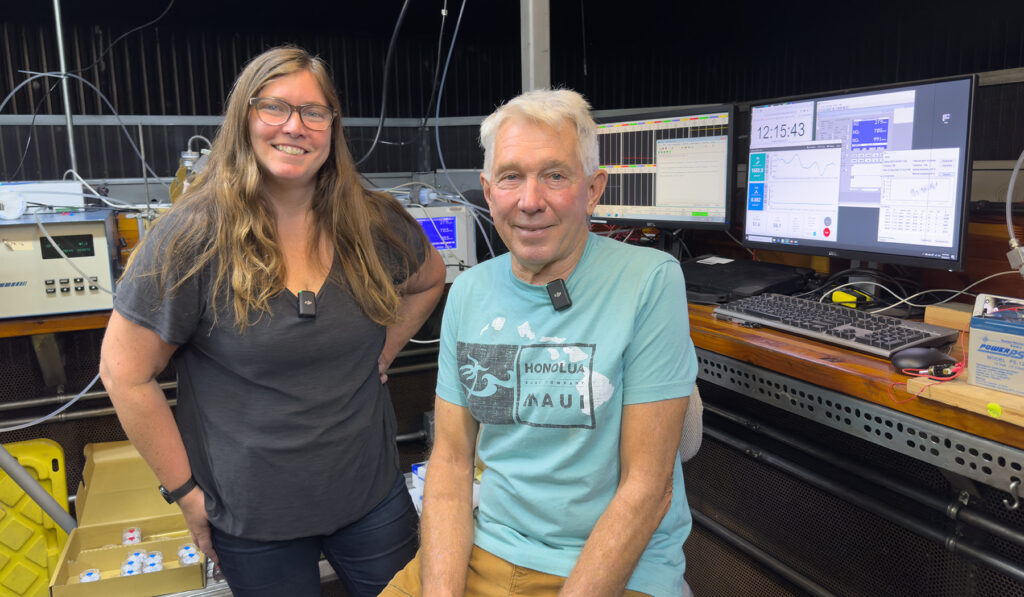

USFS scientists Steve Baker and Emily Lincoln in the “crows nest”, USFS Fire Science Lab / Baltar

Comments are closed