About Biochar

Biochar is a specialized form of charcoal that is produced by heating biomass using high heat (typically 350 C to 1000 C) in low-oxygen environments, and that is suitable for use in agriculture. It is commonly used as a soil amendment (typically combined with compost) to increase soil health, conserve and store nutrients and water, and in many cases increase agricultural crop yields. Researchers are also discovering many other uses for biochar, including stormwater filtration, as a feed supplement in dairy and poultry operations, and even as a beneficial additive in concrete production and construction materials.

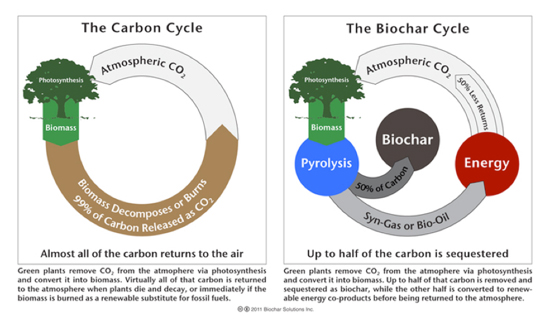

When biomass is converted to biochar and added to soils it is turned into a very stable form of carbon that microorganisms cannot use for a food source, so it degrades very slowly. As such, it is a form of carbon sequestration that can be implemented by anyone from a backyard vegetable gardener to the largest farm in California’s Central Valley. It is currently in high demand for use as a carbon offset protocol on the European voluntary market, as most of it can last for centuries and it is easily measured and verifiable. Biochar production and use is increasingly viewed as an important “natural climate solution” by a wide array of organizations including the Intergovernmental Panel on Climate Change (IPCC), the Nature Conservancy, The U.S. Natural Resources Conservation Service, and Lawrence Livermore National Lab.

Biochar is not a single type of material, but rather the catch-all name for a wide spectrum of carbonized biomass made from different feedstocks, at different temperatures, using processes called pyrolysis or gasification that also produce a variety of other valuable byproducts such as process heat, producer gases, and pyrolytic fluids such as wood vinegar.

Biochar can be made from many different sustainable feedstocks such as surplus forestry materials from mills, fuels reduction slash generated in high fire risk areas, vineyard, orchard and some crop residues, and from materials generated by tree services clearing utility rights of way. In general, the higher the density and lignin content of the feedstock the more biochar will be produced, so woody materials are most commonly sought after and used.

Biochars can also be made at lower temperatures from materials like manures and grasses that can possess special and unique properties, and there is much still to learn where different types of biochars might best be used in specific soils and with specific plants. Since biochar production and use is an important “waste” management tool with multiple benefits, we support creative uses and applications. However, we may discover that the conversion of materials like manures with significant nutrient and agronomic value may be better utilized in regenerative farm management systems or composting streams rather than as feedstock for biochar.

Much of the biochar produced today comes as a byproduct of renewable biomass energy generation and with some post processing, although it can be and is easily made almost everywhere on earth in earthen pits, simple kilns, or by altering agricultural burning techniques.

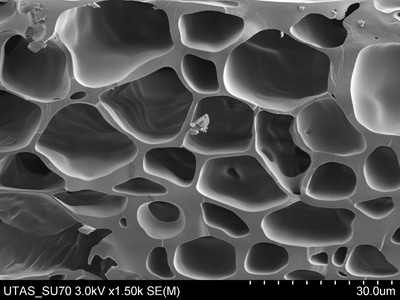

Biochar has a unique physical structure, with thousands of tiny pores that hold the nutrients and water for the plants’ roots to access and enjoy. In many ways it’s akin to a coral reef in the ocean, acting as a natural attractant, sanctuary, and incubator by creating infrastructure for billions of organisms to thrive.

Biochar is placed into the soil by farmers….in their fields of crops, in orchards, in vineyards. The best time to apply it is with new plantings, but there are ways to add it using no-till nutrient application techniques in existing fields or orchards. Field tests have shown that the worse the soil’s characteristics are when the biochar is added to it, the more positive the impact will be on crop yields.

We strongly believe that biochar should be made ONLY from sustainably managed sources, which is critical from both an environmental and business perspective, and that when sourcing biomass from forest environments great care must be taken to preserve and minimize damage to forest ecosystems.

While some rapidly growing woody biomass materials, such as that produced by small-holder bamboo farms in developing countries, are certainly better than cutting slow-growing trees to produce biochar, we encourage agricultural models that move away from mono-cropping and that embrace increased biodiversity and regenerative techniques as the models of the future.

There is more than enough misdirected and poorly managed biomass to provide material for a healthy, sustainable biochar industry in the coming decades. We are strong supporters of James Amonette’s “Climate Star” and Climate Action’s carbon credit initiatives that seek to establish industry-wide standards for rating biochar’s carbon sequestration value.

We also well understand that biochar production is a regional activity and that hauling biomass over long distances is not viable from an economic or an environmental standpoint. So, we support construction of regionally-located, biomass-to-biochar conversion centers organized by “carbonsheds” that would determine appropriate feedstock sources and technology sizes and types based on site-specific situations. Just as with distributed energy generation, we need a distributed network of biochar and compost operations (preferably integrated) that utilize local “waste” streams and minimize transportation costs and GHG impacts.

Biochar mixed with compost makes a rich soil amendment for your farm, ranch or garden.

Once large volumes of biochar are available for commercial use, it can be used widely around the world by literally millions of farmers. Imagine the impact in Africa and Eastern Europe and Southeast Asia and Patagonia. In almost every country, biochar can be added economically to fields to increase resiliency to drought and increase production, in pasture land to improve grass production, to dairy operations to reduce odors, and improve animal health, and reduced the enteric methane produced during digestion. Cooperatives could be set up to share investment costs in conversion machines and/or simply teach low-polluting and low-investment biochar production techniques.

In many settings, we could get farmers and ranchers to “donate” their woody wastes to the biochar production unit operators and receive in exchange not cash but biochar. The same truck that brought the waste wood to the production site (assembly area) could be used to return bags of biochar to the same farmer. The world could shift from patterns of “slash and burn” agriculture to “slash and char” instead.

Biochar production and use prevents a large percentage of the C02 contained in the feedstock from returning to the atmosphere. Renewable energy made from biochar production can be considered carbon negative, depending on how it is produced, transported, and applied. According to the book “Burn: Using Fire to Cool the Earth”, by Albert Bates and Kathleen Draper, the estimated annual amount of C02e that could be sequestered through biochar production and use in agriculture is 1.7 GT. However, this figure could be increased 25 to 30-fold if biochar is used to partially displace a number of common industrial materials including construction aggregates and filtration media, sand and asphalt, while also adding carbon negative energy to a specific location or into the grid.